Gas Suppression System: The Backbone of Modern Fire Protection in High-Risk Saudi Facilities

Introduction: Why Gas Suppression Systems Matter More Than Ever

A gas suppression system has become one of the most relied-upon fire protection solutions in Saudi Arabia’s most sensitive environments. As the Kingdom continues to expand its industrial, digital, and energy infrastructure, traditional fire suppression methods are no longer sufficient for spaces where water or foam could cause irreversible damage. Facilities such as data centers, control rooms, laboratories, and oil and gas installations demand a response that is fast, precise, and clean.

Unlike conventional systems, gas suppression systems extinguish fires without leaving residue or damaging equipment. This makes them a cornerstone of modern fire suppression technology, especially in locations where downtime translates directly into financial loss or operational risk. From an operational and regulatory standpoint, these systems also align closely with Saudi Civil Defense requirements and Saudi Building Code obligations, making them not only a safety choice but a compliance necessity.

This article explores gas suppression systems from a practical, regulatory, and strategic perspective, grounded in real-world Saudi applications and aligned with international fire suppression standards.

Understanding the Concept of a Gas Suppression System

At its core, a gas suppression system is designed to detect and suppress fire in its earliest stages by releasing a gaseous agent into an enclosed space. The agent works either by interrupting the chemical reaction of the fire or by reducing oxygen levels to a point where combustion can no longer continue. What distinguishes these systems is their ability to act rapidly without harming valuable assets.

In Saudi facilities, these systems are typically integrated with automatic fire suppression systems that include advanced detection, control panels, and warning mechanisms. Once smoke or heat is detected, the system activates a timed discharge, allowing occupants to evacuate before the agent is released. This combination of speed, safety, and precision explains why gas systems are increasingly specified for critical infrastructure protection across the Kingdom.

The reliance on gas-based systems is particularly strong in sectors where electronics, data integrity, or hazardous processes are involved. Water-based solutions may extinguish a fire, but the collateral damage they cause can be just as destructive as the fire itself.

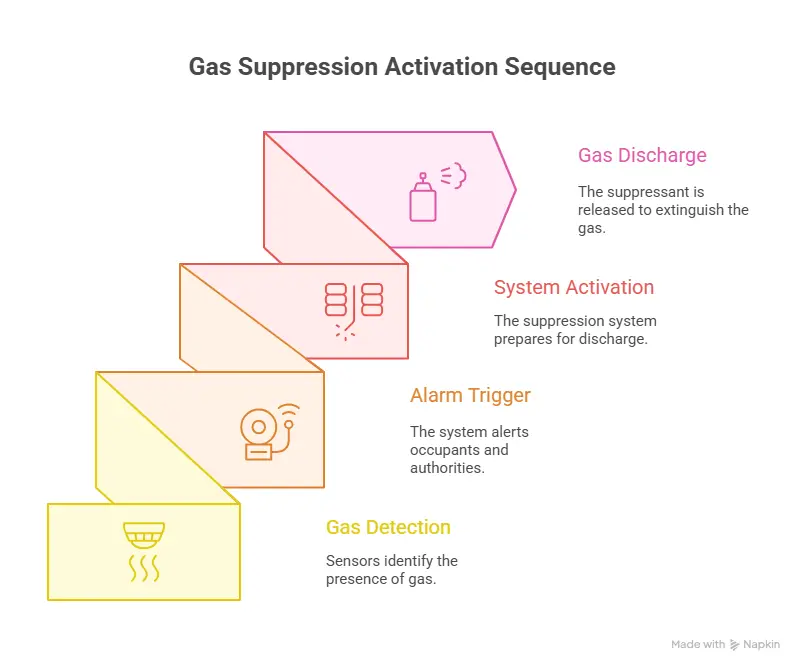

How Gas Suppression Systems Work in Practice

A gas suppression system follows a carefully sequenced process that balances human safety with fire risk management. Detection devices continuously monitor the protected area, identifying early signs of fire before flames can spread. Once triggered, the control panel initiates alarms and countdown signals, preparing occupants for evacuation.

After the delay period, the suppression agent is discharged through strategically placed nozzles, flooding the enclosure in seconds. The fire is extinguished almost instantly, limiting heat damage and preventing re-ignition. This rapid response is essential in environments such as server rooms or industrial control centers, where even seconds of fire exposure can compromise operations.

This structured process is one of the reasons gas systems are favored in high-risk Saudi applications, where precision and predictability are essential.

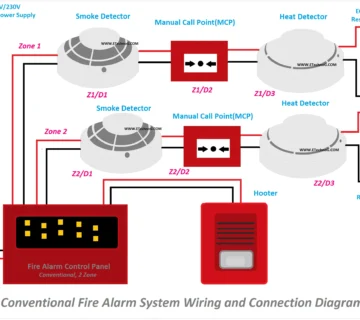

Key Components That Define System Performance

Every gas suppression system is built around a set of interdependent components that must function seamlessly together. Cylinders store the suppression agent under pressure, while detection devices ensure early activation. Control panels coordinate alarms, delays, and discharge signals, and nozzle networks distribute the agent evenly across the protected space.

The reliability of these components directly affects system effectiveness and regulatory approval. Saudi Civil Defense inspections place significant emphasis on system integrity, room sealing, and correct nozzle placement. Any weakness in design or installation can compromise performance and lead to non-compliance during inspections.

For this reason, suppression system installation must always be carried out by licensed contractors who understand both NFPA guidelines and local Saudi regulations. Experience in local approval processes is often the difference between a smooth handover and costly rework.

Types of Gaseous Agents Used in Saudi Arabia

Not all gas suppression systems use the same agents, and selecting the right one depends heavily on the nature of the protected space. Clean agent fire suppression systems such as FM-200 and Novec 1230 are widely used in occupied areas because they are safe for people and leave no residue. These agents suppress fire chemically, stopping combustion without reducing oxygen to dangerous levels.

Inert gas systems, such as Inergen, work by lowering oxygen concentration while remaining breathable for short periods. They are often chosen for data centers where environmental impact is a concern. Carbon dioxide systems, while effective, are typically limited to unoccupied or strictly controlled areas due to the risk they pose to human life.

In Saudi Arabia, there is a growing preference for environmentally responsible agents, driven by sustainability goals and international environmental commitments. This trend aligns well with advanced fire protection systems designed for long-term operational resilience.

Clean Agent Systems vs. CO₂: A Strategic Comparison

Choosing between clean agent fire suppression and CO₂ systems is not simply a technical decision. It is a strategic one that affects safety protocols, operational continuity, and compliance requirements. Clean agents are ideal for spaces where human presence is expected, offering fast suppression without health risks. CO₂ systems, on the other hand, are cost-effective and powerful but require strict evacuation controls.

In Saudi oil and gas facilities, CO₂ systems are often reserved for unmanned areas, while clean agents dominate in control rooms and data environments. Understanding these distinctions is essential for aligning fire suppression technology with real operational needs.

Regulatory Landscape Governing Gas Suppression in Saudi Arabia

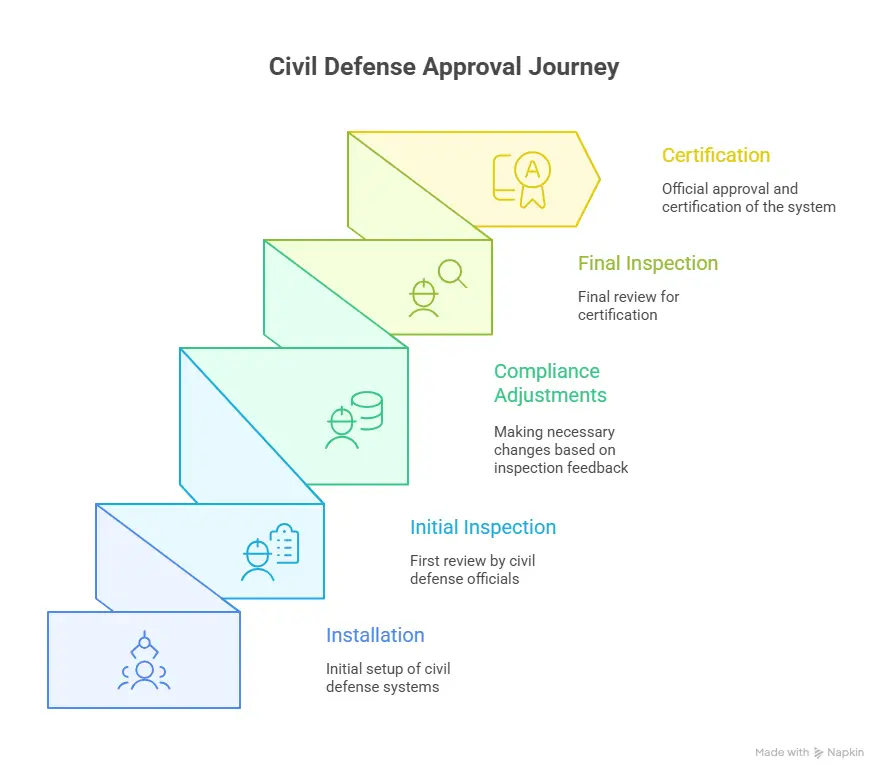

Gas suppression systems in Saudi Arabia must comply with a layered regulatory framework that includes Saudi Building Code provisions, Civil Defense requirements, and international fire suppression standards such as NFPA 2001. Approval processes are rigorous, involving design reviews, installation inspections, and performance testing.

Room integrity testing is a critical requirement, ensuring that the enclosure can retain the suppression agent long enough to extinguish the fire effectively. Without this, even the most advanced system may fail during an actual incident. Compliance is not a one-time event but an ongoing responsibility that extends through maintenance and periodic inspections.

DARS’s approach emphasizes compliance as a continuous process, integrating fire safety compliance into every stage of system lifecycle management.

The Role of Risk Assessment in System Design

Effective gas suppression begins long before installation. Risk assessment plays a central role in determining agent type, cylinder sizing, discharge timing, and nozzle layout. Each protected space presents unique challenges, from airflow patterns to equipment density.

Suppression System Installation in Saudi Facilities

The effectiveness of a gas suppression system is ultimately determined on site, not on paper. Even the most advanced fire suppression technology can fail if installation does not strictly follow approved designs and Saudi regulatory requirements. In the Kingdom, installation is not treated as a routine construction activity but as a regulated safety process that must be executed by licensed contractors and reviewed by Civil Defense authorities.

During installation, precision is critical. Cylinders must be positioned to allow correct discharge pressure, pipe networks must be calculated to avoid flow imbalance, and nozzles must be aligned to ensure uniform gas distribution. Any deviation can compromise discharge concentration, reducing the system’s ability to suppress fire within the required timeframe. This is why suppression system installation is tightly linked to engineering calculations defined by international fire suppression standards.

What distinguishes professional installations in Saudi Arabia is their integration with local approval workflows. Each step is documented, tested, and validated to ensure the system is not only operational but also legally acceptable for occupancy and insurance purposes.

Commissioning and Civil Defense Approval

Once installation is complete, commissioning becomes the most critical phase before a gas suppression system can be officially handed over. Commissioning verifies that every component operates exactly as designed under simulated fire conditions. Detection devices are tested, alarms are activated, control panels are verified, and discharge logic is confirmed.

Saudi Civil Defense requires witnessed testing and documented evidence that the system meets approved design criteria. Room integrity testing is a central part of this process, ensuring that the enclosure can retain the gaseous agent for the required hold time. Without this test, even a perfectly installed system may be rejected, delaying project completion and operational readiness.

This approval stage reinforces the importance of working with contractors who understand not only technical requirements but also the administrative and inspection expectations unique to Saudi Arabia.

Why Room Integrity Testing Is Non-Negotiable

Room integrity testing is often misunderstood as a formality, but in reality it is a performance guarantee. Gas suppression systems rely on maintaining a specific concentration of agent for a defined duration. If the room leaks excessively, the gas dissipates too quickly, allowing the fire to re-ignite.

In Saudi facilities, room integrity testing is mandatory for spaces protected by clean agent fire suppression or inert gas systems. The test identifies leakage points around doors, cable penetrations, raised floors, and ceiling voids. Addressing these weaknesses is essential for ensuring that the system delivers real fire risk management, not just regulatory compliance.

From an operational perspective, integrity testing also protects long-term investment. It reduces the likelihood of failed inspections, unplanned retrofits, and system underperformance during actual fire incidents.

Integration with Other Fire Safety Systems

A gas suppression system does not operate in isolation. In modern Saudi buildings, it is part of a broader fire safety ecosystem that includes alarms, emergency lighting, ventilation controls, and sometimes water-based systems. Proper integration ensures that all systems respond coherently during an incident.

For example, ventilation systems must shut down automatically before gas discharge to prevent agent loss. Fire alarms must coordinate evacuation warnings with suppression delays. In some facilities, gas systems are paired with sprinklers as a layered protection strategy, balancing rapid suppression with structural fire control.

This integrated approach reflects the shift toward advanced fire protection systems that prioritize coordination rather than isolated responses.

Maintenance as a Strategic Responsibility

Once operational, a gas suppression system enters its longest and most critical phase: maintenance. In Saudi Arabia, maintenance is not optional or reactive. It is a regulated obligation tied directly to Civil Defense certification and insurance validity. Systems must be inspected regularly to confirm cylinder pressure, detection sensitivity, and control panel functionality.

Neglecting maintenance can lead to undetected leaks, sensor failures, or degraded discharge performance. These issues often remain invisible until inspections or, worse, an actual fire event. For this reason, maintenance contracts are increasingly viewed as part of broader industrial fire safety solutions rather than simple service agreements.

Consistent maintenance also supports fire safety compliance by ensuring documentation is always inspection-ready. In high-risk sectors such as oil and gas or data infrastructure, this level of readiness is essential for uninterrupted operations.

Common Operational Challenges in Gas Systems

Despite their reliability, gas suppression systems are not immune to operational challenges. False discharges can occur due to poorly calibrated sensors or environmental interference, leading to unnecessary downtime and agent refill costs. In other cases, system performance is compromised by gradual room leakage caused by facility modifications.

Addressing these challenges requires proactive system audits and coordination between facility managers and fire protection specialists. Regular reviews help identify risks before they escalate, preserving both safety and operational continuity. This proactive mindset is central to effective fire risk management in Saudi industrial environments.

Cost Considerations and Long-Term Value

The cost of a gas suppression system varies depending on agent type, room volume, and system complexity. Clean agents typically involve higher upfront investment, but they offer significant long-term value by minimizing downtime, asset loss, and post-incident recovery costs. In contrast, lower-cost solutions may appear attractive initially but often carry higher operational risk.

In Saudi Arabia, cost decisions are increasingly influenced by lifecycle value rather than installation price alone. As industrial expansion accelerates under Vision 2030, organizations are prioritizing systems that support resilience, compliance, and sustainability. This shift reinforces the strategic role of gas suppression systems as long-term protection assets rather than short-term safety expenses.

Preparing for the Future of Fire Suppression

Fire suppression standards and technologies continue to evolve, particularly around environmental impact and system intelligence. Saudi facilities are already beginning to adopt next-generation clean agents and smarter detection technologies that enhance response accuracy and reduce false activations.

This evolution places greater responsibility on system owners to stay informed and adaptable. Choosing scalable solutions today ensures compatibility with future regulations and operational demands. It also positions facilities to meet emerging expectations around sustainability and digital integration.

Real-World Applications Across Saudi Industries

The value of a gas suppression system becomes most evident when viewed through real-world applications. In Saudi Arabia, these systems are heavily relied upon in data centers where uninterrupted service is critical to national and commercial operations. Even a minor fire incident in such environments can lead to data loss, reputational damage, and extended downtime. Clean agent fire suppression systems are preferred here because they protect sensitive equipment without introducing moisture or residue.

In the oil and gas sector, gas suppression plays a different but equally vital role. Control rooms, turbine enclosures, and electrical substations are often protected by systems designed to operate in harsh conditions and under strict safety protocols. In unmanned zones, CO₂ systems are still widely used due to their effectiveness and cost efficiency, while occupied areas rely on safer alternatives that align with international fire suppression standards and Saudi regulations.

These varied applications demonstrate how gas suppression systems adapt to different operational risks while maintaining a consistent objective: rapid fire control with minimal disruption.

Supporting Business Continuity and Operational Resilience

Beyond fire extinguishment, a gas suppression system directly supports business continuity. Fires in critical environments rarely cause damage only through flames. Smoke, heat, and secondary system failures often account for the majority of losses. By suppressing fires at their earliest stages, gas systems significantly reduce these cascading effects.

This capability is particularly relevant in Saudi Arabia’s expanding digital and industrial landscape. As facilities become more interconnected, a single incident can impact multiple operations simultaneously. Advanced fire protection systems help organizations manage this complexity by reducing recovery time and limiting operational exposure.

From a strategic standpoint, this aligns fire risk management with broader organizational resilience goals. Fire protection is no longer a compliance checkbox; it is a core component of operational planning.

Aligning Gas Suppression with Vision 2030 Development

Saudi Arabia’s Vision 2030 has accelerated the development of technology hubs, industrial cities, and smart infrastructure. These environments demand fire protection solutions that are fast, intelligent, and environmentally responsible. Gas suppression systems, particularly those using modern clean agents, fit naturally into this vision.

As sustainability becomes a growing priority, facilities are increasingly selecting agents with low environmental impact and long-term regulatory acceptance. This shift supports national objectives while ensuring compliance with evolving global standards. It also reduces the risk of future system obsolescence caused by environmental phase-outs.

By aligning fire suppression technology with national development goals, organizations future-proof both their assets and their compliance strategies.

Performance Optimization Through Ongoing Evaluation

Installing a gas suppression system is not the end of the journey. Performance optimization requires periodic evaluation of system effectiveness as facility conditions change. Equipment upgrades, layout modifications, and increased occupancy can all influence how a system performs during an incident.

Regular audits help identify whether discharge concentrations remain adequate and whether detection coverage is still appropriate. These evaluations are especially important in high-growth Saudi facilities, where operational changes are frequent. Proactive assessment ensures that fire safety compliance keeps pace with expansion rather than lagging behind it.

This approach transforms maintenance from a routine obligation into a strategic tool for continuous improvement.

Choosing the Right Partner for Long-Term Protection

The success of any gas suppression system depends heavily on the expertise behind it. From initial risk assessment to ongoing maintenance, every phase requires a deep understanding of local regulations, international standards, and real-world operational demands. In Saudi Arabia, this expertise is particularly critical due to strict Civil Defense oversight and complex approval processes.

Organizations benefit most when they work with partners who view fire protection as a long-term responsibility rather than a one-time project. This mindset ensures consistent system performance, smoother inspections, and faster response to emerging risks. It also reinforces trust between facility owners, regulators, and insurers.

Selecting the right partner is therefore as important as selecting the right technology.

Looking Ahead: The Future of Gas Suppression Systems

The future of gas suppression systems is closely tied to innovation in detection, monitoring, and sustainability. Smart sensors, predictive maintenance tools, and environmentally advanced agents are reshaping how fire protection systems are designed and managed. Saudi Arabia is well positioned to adopt these advancements as part of its broader digital transformation.

Facilities that invest early in adaptable systems will find it easier to integrate new technologies and comply with future regulations. This adaptability ensures that fire suppression remains effective even as operational demands evolve.

By planning with the future in mind, organizations can ensure that their fire protection strategies remain relevant, compliant, and resilient.

Conclusion: Gas Suppression as a Strategic Asset

A gas suppression system is far more than a fire safety measure. In the Saudi context, it is a strategic asset that protects critical infrastructure, supports compliance, and safeguards business continuity. Its ability to extinguish fires quickly and cleanly makes it indispensable in environments where traditional methods fall short.

As industries grow and risks become more complex, the role of advanced fire protection systems will continue to expand. Organizations that approach gas suppression with a long-term, integrated mindset will be better equipped to manage risk, meet regulatory expectations, and protect their most valuable assets.