Introduction

A foam extinguishing system is a fire suppression arrangement that uses a specially formulated foam concentrate mixed with water and air to produce a foam blanket. That foam blanket cushions and isolates fuel surfaces from oxygen and cools the fire zone, making it highly effective for Class B (flammable liquid) hazards. In sectors like oil, petrochemical plants, aviation, and storage terminals, foam systems often outperform water-only solutions.

In Saudi Arabia’s industrial landscape, foam systems serve as essential fire protection solutions. They address high-risk operations, mitigate risks tied to flammable liquids, and support compliance with civil defense and environmental regulations. As the kingdom continues expanding its industrial and energy sectors, understanding the design, regulation, and best practices around foam systems becomes crucial.

Regulatory pressures, environmental concerns (especially around PFAS / PFOS), and evolving international standards all influence how foam extinguishing systems are specified, maintained, and approved in Saudi Arabia. In the coming sections, DARS unpacks the key aspects you need to know to design, deploy, maintain, and comply with foam-based fire safety.

What Is a Foam Extinguishing System and How Does It Work?

A foam extinguishing system comprises several interlinked components: foam concentrate storage, proportioning units or mixers, a reliable water supply, piping or delivery infrastructure, nozzles or monitors, and control devices. When a fire is detected or manually triggered, the system draws the foam concentrate, mixes it in precise proportion with water (and often air), then delivers the foam under pressure to the hazard zone. The foam forms a stable blanket that smothers vapors, suppresses rekindling, and cools hot surfaces.

Mechanistically, the foam acts in three main ways: (a) separation creating a protective barrier between the fuel and flame; (b) vapor suppression arresting vapors that feed combustion; and (c) cooling absorbing heat to lower temperatures below ignition thresholds. In many systems, especially automatic extinguishing systems, the mixing is triggered by detection or control logic without manual intervention.

Foam systems use different types of foam agents, such as aqueous film-forming foam (AFFF), alcohol-resistant foams, protein-based foams, and fluorine-free formulations. In Saudi Arabia, AFFF and alcohol-resistant variants (AR-AFFF) are common in fuel or solvent applications. The choice depends on the fuel class, site conditions, and regulatory acceptance.

Why Are Foam Extinguishing Systems Essential in Saudi Arabia?

In Saudi Arabia’s industrial sectors oil refining, petrochemical processing, fuel storage, aviation, and logistics flammable liquid fires are a major hazard. A foam extinguishing system provides a targeted, effective means of suppressing these risks where water alone may fail. Many facilities are required by civil defense compliance to deploy such systems as part of their risk mitigation and fire risk management strategy.

Furthermore, regulatory agencies in Saudi Arabia enforce technical standards for firefighting systems and materials. For example, the Saudi Standards, Metrology and Quality Organization (SASO) publishes a Technical Regulation for Fire Control Materials and Equipment that governs quality, performance, and safety of firefighting equipment including foam systems. Also, national building and fire codes, such as those under SBC 801, outline minimum requirements for fire safety designs including foam-based suppression in certain industrial occupancies.

In hot, dusty, and demanding climatic environments, foam systems provide resilience. They help protect life, property, and mission-critical infrastructure. For a business operating in Saudi Arabia, deploying a properly designed foam suppressant system is not just best practice, it’s often a requirement for regulatory approval and insurance acceptance.

What Types of Foam Systems Are Used and How Are They Selected?

System Variants

There are multiple types of foam-based systems deployed depending on the hazard scenario:

- Deluge foam systems: All nozzles open simultaneously, flooding the area with foam.

- Foam sprinkler systems: Like conventional sprinklers but with foam-water mix.

- Pre-action foam systems: A hybrid approach where detection triggers foam flow.

- Portable foam extinguishers: Handheld units for smaller or localized risks.

Choosing among them often depends on risk profile, hazard size, availability of detection systems, and architectural constraints. For example, a tank farm might favor a deluge system, while fuel loading racks may use fixed monitors or portable foam units.

Selection Criteria

When selecting a foam system one should consider:

- Fuel and hazard type: Hydrocarbon vs. alcohol / solvent fuels require compatible foam (e.g. AR-AFFF).

- Site layout and exposure: Obstructions, wind, and spill risk affect nozzle placement and coverage.

- Regulatory approvals: SASO, Saudi Civil Defense, and international standards like NFPA may restrict certain foam types.

- Environmental and health considerations: The phase-out of PFOS/PFAS compounds has driven interest in fluorine-free foams. Many jurisdictions are pushing toward more environmentally friendly foam agents.

The global trend toward safer, PFAS-free foam formulations is already influencing procurement and engineering decisions. Suppliers in Saudi Arabia are responding by offering firefighting foam products that meet or exceed NFPA performance while avoiding legacy contaminants.

Regulations, Maintenance & Innovation

Maintenance and Inspection Requirements

Like any fire suppression system, a foam extinguishing installation demands consistent maintenance and thorough inspection to ensure reliability. Foam equipment is often deployed in critical environments where even brief downtime can pose significant risk. Regular inspection helps guarantee that the foam concentrate, proportioning units, and delivery mechanisms remain in peak condition. The process involves evaluating the physical integrity of tanks and piping, verifying proportioner calibration, and confirming that all discharge devices are unobstructed and functional.

Maintenance also extends to environmental and chemical stability. Foam concentrates can degrade over time, particularly under extreme heat or contamination. Periodic laboratory testing often performed annually assesses pH levels, viscosity, expansion ratio, and drainage time. These parameters directly influence the foam’s ability to smother and cool fires effectively. At DARS, adherence to manufacturer recommendations and NFPA standards ensures every client’s system functions with full reliability.

Equally important is documentation. Proper record-keeping is essential for civil defense compliance in Saudi Arabia. Maintenance logs, inspection certificates, and test results must be archived for verification during audits by the Saudi Civil Defense or insurance authorities. This administrative diligence reflects an organization’s overall fire risk management maturity and strengthens its safety reputation within regulated industries.

Regulatory Framework and Applicable Standards

Saudi Arabia’s fire protection regulations are among the most rigorous in the region, ensuring that all installations comply with global best practices while accommodating the kingdom’s industrial realities. The Saudi Standards, Metrology and Quality Organization (SASO) and the Saudi Civil Defense Authority form the backbone of this framework. Their Technical Regulation for Fire Control Materials and Equipment defines performance, labeling, and testing requirements for foam systems and related components. These local frameworks often draw reference from international authorities such as NFPA 11 (Standard for Low-, Medium-, and High-Expansion Foam) and NFPA 16 (Foam-Water Sprinkler and Foam-Water Spray Systems). (NFPA.org)

Moreover, environmental considerations are reshaping the regulatory landscape. The global move to phase out PFOS and PFAS compounds, chemicals once common in foam formulations, has reached Saudi Arabia’s industrial sector. Authorities encourage adoption of fluorine-free alternatives to align with international conventions such as the Stockholm Convention on Persistent Organic Pollutants. (UNEP.org) DARS’s approach emphasizes selecting eco-conscious products that meet both local certification and sustainability benchmarks.

For engineers and facility managers, compliance extends beyond installation. Systems must be inspected and certified by accredited bodies before operation. Re-certification occurs periodically, ensuring that any system modifications or expansions maintain full conformity. By partnering with approved contractors and adhering to NFPA and SASO standards, businesses protect not only their assets but also their operational legitimacy under Saudi law.

Integration with Emergency Response Systems

A foam extinguishing system achieves its full potential only when integrated within a broader emergency response system. Early detection, automated alarms, and coordinated evacuation protocols are as vital as the foam discharge itself. DARS emphasizes synergy between detection networks like heat or flame detectors and suppression mechanisms, enabling instantaneous activation and rapid containment of fire events.

This integration is especially critical in large industrial sites where communication between fire pumps, control panels, and emergency teams can determine the difference between containment and catastrophe. Advanced systems now feature networked controllers linked through SCADA or IoT frameworks. They allow real-time monitoring of tank levels, valve positions, and discharge pressures. Such digital oversight supports predictive maintenance, reducing false activations while ensuring readiness during actual emergencies. (Honeywell.com)

In practice, integration aligns with Vision 2030 objectives promoting smarter, more sustainable infrastructure. By embedding fire protection technology within a unified digital architecture, facilities can strengthen industrial resilience while reducing maintenance costs and environmental impact. DARS collaborates with technology partners to provide end-to-end solutions from installation to data-driven system management that elevate national safety standards.

Trends and Innovations in Foam Fire Protection

Technological advancement and sustainability are transforming how fire protection solutions are designed and deployed across Saudi Arabia. One of the most notable trends is the adoption of fluorine-free foam agents. These formulations provide equal or superior firefighting performance without persistent pollutants. As more international airports, energy plants, and logistics hubs transition to green foams, suppliers in the kingdom are scaling up research and certification efforts. (Viking-Life.com)

Simultaneously, next-generation proportioning technologies enhance precision and reduce waste. Electronic or balanced-pressure proportioners maintain accurate foam-to-water ratios regardless of flow fluctuation, ensuring consistent quality of the firefighting foam. Automated test modules now permit verification without physical discharge, conserving resources and preventing contamination. These innovations align with environmental and operational efficiency goals central to modern industrial fire safety.

Another emerging trend involves remote system analytics. Through digital dashboards, operators can visualize system health, schedule maintenance, and detect anomalies before they escalate into failures. Predictive analytics powered by machine learning help optimize readiness while minimizing downtime. Such capabilities illustrate the broader shift from reactive fire protection to proactive risk management, a shift DARS actively integrates into its client offerings.

Training and Human Readiness

Even the most advanced foam extinguishing system relies on human understanding for successful operation. Personnel must be trained not only to initiate manual discharge but also to interpret alarms, conduct visual inspections, and coordinate with civil defense responders. Training sessions often simulate spill and ignition scenarios, familiarizing teams with foam behavior and coverage patterns.

DARS’s training philosophy bridges technical knowledge with regulatory awareness. Courses cover system operation, maintenance protocols, and emergency communication procedures, ensuring that employees can act decisively and confidently. Regular refresher programs align with Saudi Civil Defense directives, which emphasize continuous competency development for safety personnel.

This focus on human factors reinforces a culture of prevention rather than reaction. It also supports long-term compliance: properly trained operators reduce equipment misuse, prolong component life, and ensure every inspection or test is executed according to recognized standards.

Choosing the Right Partner & Building a Safer Future

How to Choose a Reliable Foam Extinguishing System Provider in Saudi Arabia

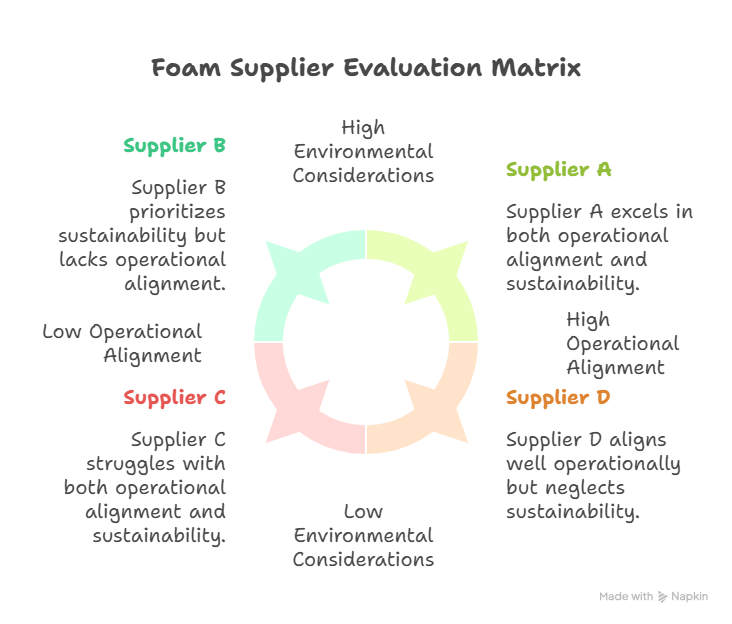

Selecting a foam extinguishing system provider requires more than comparing catalogues or prices; it’s a decision that affects lives, compliance, and operational continuity. The provider must not only deliver high-quality components but also ensure full alignment with Saudi Civil Defense requirements and NFPA standards. Certifications, local experience, and technical competence form the foundation of reliability.

DARS emphasizes that choosing a supplier begins with understanding the system’s intended purpose. A reliable contractor offers end-to-end consultation from risk assessment and hydraulic calculations to system design, installation, and commissioning. Their ability to customize fire protection solutions based on the client’s risk profile is what distinguishes professional providers from simple distributors. This personalized approach guarantees that every foam system meets environmental, structural, and operational expectations.

Equally important is after-sales support. Foam extinguishing systems demand periodic testing and adjustments to maintain peak efficiency. Providers should therefore include maintenance programs, foam concentrate replacement plans, and emergency service guarantees. Companies that hold local approvals, maintain spare-parts availability, and have field engineers trained on the latest fire suppression system technologies provide a level of assurance that imported or uncertified vendors cannot.

Sustainability and Environmental Responsibility

The global movement toward sustainable industrial operations has reached fire safety engineering, driving a paradigm shift in how foam extinguishing systems are formulated and maintained. Historically, firefighting foams contained fluorinated compounds such as PFOS and PFAS, which persist in the environment. Recognizing these concerns, regulators and safety leaders in Saudi Arabia are promoting fluorine-free foam alternatives that maintain high performance while reducing ecological impact.

DARS supports this transition through education and advocacy. The company prioritizes sourcing foam agents verified by independent laboratories to meet eco-efficiency criteria without sacrificing firefighting capability. This proactive stance mirrors international best practices outlined by environmental authorities and ensures clients remain compliant with both local and global expectations. (Viking-Life)

Sustainability also extends beyond product composition. Modern systems can minimize waste by integrating recirculation lines and electronic proportioning modules that precisely control foam concentrate usage. This optimization lowers costs while demonstrating corporate commitment to environmental stewardship, a growing factor in industrial auditing and ISO certification processes across Saudi Arabia.

Aligning Foam Extinguishing Systems with Vision 2030

Saudi Arabia’s Vision 2030 blueprint encourages innovation and resilience across all sectors, including safety infrastructure. Fire protection is a crucial part of national industrial development, ensuring that progress occurs without compromising human or environmental welfare. Foam extinguishing systems contribute directly to this mission by protecting facilities vital to energy, logistics, and manufacturing.

By promoting local expertise, technology transfer, and knowledge sharing, Vision 2030 also empowers Saudi companies to develop their own high-performance foam technologies. This aligns with DARS’s philosophy of enabling sustainable, home-grown safety ecosystems rather than relying solely on imports. The long-term goal is clear: establish Saudi Arabia as a regional leader in industrial fire safety balancing innovation, compliance, and environmental care.

Case Studies and Practical Implementation

Across Saudi Arabia, foam extinguishing systems have proven indispensable in high-risk environments such as fuel depots, petrochemical complexes, and airports. Each facility presents unique challenges: temperature fluctuations, corrosion, wind exposure but the consistent outcome is enhanced safety. DARS’s projects illustrate how local expertise combined with international compliance creates reliable systems capable of saving both lives and infrastructure.

For instance, oil-storage terminals along the Eastern Province utilize deluge foam systems designed to control large-scale pool fires within seconds of ignition. In contrast, commercial hangars near Riyadh implement foam-water sprinkler systems that deliver rapid, automated response with minimal water consumption. In both cases, the integration of sensors, proportioning technology, and operator training ensures unmatched readiness and precision.

These examples demonstrate that foam systems are not generic installations; they are strategic investments customized for each risk environment. The result is measurable reduction in fire-related downtime, lower insurance costs, and improved corporate safety ratings tangible benefits that extend beyond compliance alone.

Common Challenges and How to Overcome Them

Despite their proven efficiency, foam systems face challenges, particularly in maintenance and environmental adaptation. Harsh climates can accelerate material wear, while foam degradation can compromise performance if left unchecked. The key to overcoming these challenges lies in preventive strategy. Facilities must institute structured maintenance calendars, conduct lab testing of foam samples, and routinely calibrate proportioning devices.

Another challenge involves aligning system upgrades with evolving civil defense compliance standards. Saudi regulations continuously evolve to integrate new technologies and environmental directives. Companies should therefore maintain active communication with licensed contractors and authorities to anticipate changes before they become mandatory. DARS assists clients through compliance audits and ongoing advisory services that simplify this process.

A third challenge: cost perception often discourages investment in comprehensive systems. However, the long-term savings derived from reduced incident risk, lower premiums, and increased asset lifespan far outweigh initial expenses. Educating stakeholders on this economic logic remains part of DARS’s mission to foster a safety-first business culture.

The Future of Fire Safety in Saudi Arabia

The evolution of fire protection technology is accelerating. Integration with digital monitoring systems, AI-driven maintenance alerts, and green foam formulations will soon redefine the standard for automatic extinguishing systems. Saudi Arabia’s commitment to modernization ensures that its industrial and commercial infrastructure will adopt these advancements rapidly, reinforcing its position as a regional benchmark for safety innovation.

DARS continues to pioneer this evolution by merging practical field experience with modern analytics. Through partnerships with research institutions and technology developers, the company aims to enhance predictability in fire behavior and improve suppression efficiency. As sustainability and digitalization converge, foam extinguishing systems are set to become smarter, cleaner, and more efficient than ever before.

Conclusion

Foam extinguishing systems remain at the heart of Saudi Arabia’s modern fire protection solutions. From oil refineries to airports, their ability to suppress flammable liquid fires and prevent catastrophic losses underscores their indispensable role in safeguarding life and property. Compliance with NFPA standards and Saudi Civil Defense regulations ensures each system delivers performance, reliability, and environmental responsibility.

DARS’s expertise reinforces that safety is not a static achievement but an ongoing discipline. By combining advanced technologies, sustainable practices, and continuous training, organizations can build fire-resilient operations aligned with Vision 2030’s progressive framework. Whether designing new facilities or upgrading legacy infrastructure, prioritizing a reliable foam extinguishing system is a long-term investment in security, sustainability, and national advancement.