The Role of Foam Suppression in Modern Fire Safety

Fire incidents involving flammable liquids pose a unique challenge across industrial sectors in Saudi Arabia. Unlike ordinary fires, these cannot be effectively extinguished with water alone. This is where the foam suppression system comes in an essential component of today’s fire safety solutions.

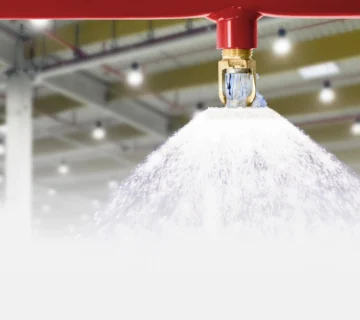

A foam suppression system uses a specialized mixture of foam concentrate, water, and air to form a dense, stable blanket that smothers flames and cools surfaces. This layer cuts off the fire’s oxygen supply while preventing fuel vapors from re-igniting. In a country with one of the world’s largest oil and petrochemical infrastructures, such technology isn’t just valuable, it’s vital for national safety and compliance.

DARS, a trusted name in Saudi Arabia’s safety and protection industry, applies its expertise in fire suppression technology to safeguard high-risk environments. From oil refineries to aircraft hangars, foam suppression systems are critical to ensuring compliance with Civil Defense regulations and maintaining continuous operational safety.

What Is a Foam Suppression System and How Does It Work?

A foam suppression system operates by combining water, air, and foam concentrate through proportioning devices. The resulting foam is discharged through sprinklers, monitors, or nozzles directly onto the fire source. The foam spreads across the flammable surface, forming a barrier that both isolates the fuel and cools it simultaneously.

This system works in three essential steps:

- Foam Generation – Water and foam concentrate are mixed in precise ratios using proportioners or pumps.

- Foam Expansion – Air is introduced into the mixture to create foam bubbles, increasing the agent’s surface area.

- Foam Application – The foam is discharged to form a thick, stable layer that suppresses combustion.

In industrial settings, especially those involving oil, gas, and chemical processes, this mechanism prevents escalation from small leaks or spills into catastrophic events. According to the NFPA 11 Standard for Low-, Medium-, and High-Expansion Foam, each foam type and discharge method is selected based on fuel type, storage configuration, and hazard level.

The Main Types of Foam Suppression Systems

Not all fires require the same foam. Different situations demand specialized types of systems designed for specific applications.

Low-Expansion Foam Systems

Low-expansion systems produce foam with an expansion ratio up to 20:1. These are ideal for areas like fuel storage tanks, pump rooms, and loading bays where precise, controlled application is necessary. The foam remains dense and heavy, providing superior cooling for liquid fuel surfaces.

Medium-Expansion Foam Systems

These systems expand foam between 20:1 and 200:1, creating a light yet stable blanket that covers wider areas. Commonly found in chemical storage warehouses, they are effective for suppressing spills of flammable liquids or vapors.

High-Expansion Foam Systems

With an expansion ratio exceeding 200:1, high-expansion systems are used in enclosed spaces such as aircraft hangars, ship engine rooms, or tunnels. The foam rapidly fills the area, displacing oxygen and minimizing radiant heat.

Each category is a key part of industrial fire safety and is often used in combination with other fire protection equipment like water sprinklers or gas suppression systems to create layered safety strategies.

Why Foam Systems Are Critical for Saudi Arabia’s Industrial Sector

Saudi Arabia’s economy is deeply tied to energy, manufacturing, and logistics sectors where fire hazards are ever-present. Foam suppression systems are particularly valuable for facilities handling petroleum derivatives, chemicals, and jet fuels.

Key Application Areas:

- Oil and Gas Facilities: Storage tanks, pipelines, and loading terminals.

- Airports and Hangars: Jet fuel storage, refueling areas, and maintenance zones.

- Chemical Plants: Solvent and paint processing areas.

- Warehouses and Distribution Centers: Storage of combustible materials.

In each of these environments, traditional water-based fire systems are insufficient. Foam suppression systems ensure fire hazard prevention through rapid response and high efficiency, minimizing property damage and protecting lives.

Saudi Civil Defense regulations require that these systems adhere to approved designs, using agents certified for environmental safety and effectiveness. DARS ensures all its installations comply with the Saudi Building Code and international standards, providing full inspection and documentation support.

Regulatory Framework: Meeting Civil Defense and NFPA Standards

The Kingdom of Saudi Arabia enforces strict regulatory oversight for fire suppression installation and maintenance. The Civil Defense Authority, in alignment with NFPA 11 and NFPA 16, mandates:

- Proper design, proportioning, and testing of foam concentrates.

- Certified performance for foam discharge devices and storage systems.

- Documentation and annual inspection for compliance validation.

Moreover, environmental standards are evolving. Saudi authorities are gradually phasing out foam agents containing PFOS and PFAS due to their environmental persistence. By 2026, only fluorine-free foam agents will be approved for new installations, a move aligned with global best practices recommended by the Viking Life Environmental Foam Guide.

This shift highlights DARS’s commitment not just to safety but also to environmental stewardship, a principle embedded in every system it delivers.

Integrating Foam Systems with Broader Fire Safety Solutions

Foam suppression systems are rarely standalone setups. They are often integrated into comprehensive fire safety solutions designed to handle multiple hazard scenarios simultaneously.

A well-designed system includes:

- Detection and Alarm Integration: Foam systems activate through connected fire detection networks that identify heat or smoke signatures early.

- Automatic Control Panels: Modern systems operate as automatic foam systems, enabling instant response without manual intervention.

- Backup Power and Redundancy: Ensures uninterrupted functionality during electrical or mechanical failures.

This integrated approach improves both response time and reliability, aligning with DARS’s mission to enhance fire control systems across all industrial domains.

The Science Behind Foam Concentrates

The foam concentrate is the most crucial component of the entire suppression system. Its chemical formulation determines foam stability, expansion, and cooling properties.

Modern foam concentrates fall into three main categories:

- Protein-Based Foams: Derived from natural materials, offering excellent stability and burn-back resistance.

- Synthetic Foams (AFFF): Alcohol-resistant, suitable for fuel and solvent fires.

- Fluorine-Free Foams (F3): Environmentally friendly alternatives now being adopted globally.

Each has a specific use case depending on fire type and site conditions. DARS’s expertise ensures the right formulation and proportioning methods are applied during each fire suppression installation.

Maintenance and Testing: The Foundation of Long-Term Reliability

Installing a foam suppression system is only the beginning of ensuring protection. Its true reliability depends on consistent maintenance and performance testing. Without these, even the most sophisticated setup can fail when needed most. Regular inspections ensure that the foam concentrate retains its quality, proportioning devices remain accurate, and discharge systems respond instantly under real conditions.

In Saudi Arabia, where industrial fire safety is deeply tied to regulatory compliance, every component from foam storage tanks to nozzles must be inspected according to Civil Defense and NFPA 11 requirements. Foam concentrates naturally degrade over time due to exposure to temperature fluctuations, contamination, or aging storage containers. To counter this, qualified technicians must periodically take samples for laboratory analysis, verifying concentration levels and expansion ratios.

A well-maintained system guarantees not only operational readiness but also compliance with Saudi Building Code mandates. DARS’s maintenance philosophy emphasizes proactive checks, where potential issues such as corrosion, blocked strainers, or deteriorated seals are identified early and corrected before they pose risks. This preventive culture reflects the company’s precise maintenance approach, a standard that aligns with its commitment to protecting lives and properties.

Challenges in Foam System Maintenance

Although maintenance is a routine requirement, it comes with challenges that demand technical precision and experience. One recurring issue in Saudi environments is corrosion, especially in coastal or desert regions where humidity and dust can accelerate system wear. Corrosion inside proportioning lines or valves can disrupt accurate foam mixing, leading to weak or delayed discharge during an emergency.

Another common problem is contamination of foam concentrate. Dust particles, condensation, or cross-mixing with different foam types can affect the agent’s expansion and cooling performance. Contaminated foam produces excessive bubbles that collapse prematurely, reducing the suppression effect. Maintaining sealed tanks, controlled environments, and proper labeling of storage units are essential practices for avoiding such failures.

Beyond physical components, human error also plays a role. Lack of training or inconsistent testing schedules can result in overlooked system deficiencies. DARS addresses this gap through professional training programs, ensuring that every technician understands the exact calibration, proportioning, and documentation process required by both Saudi Civil Defense and NFPA 25 Inspection and Testing Standards.

The Role of Trained Personnel in Fire Suppression

Foam suppression systems may rely on automation, but they still depend on human expertise to function correctly. Well-trained personnel ensure that every component, from detectors to discharge monitors, works within certified tolerances. They also interpret alarm system diagnostics, conduct manual override tests, and evaluate foam discharge performance.

In complex facilities such as refineries or airports, staff must be equipped to manage emergency activation scenarios calmly and precisely. DARS reinforces this human-centered approach by providing certified training sessions that cover system design principles, inspection protocols, and troubleshooting techniques. Trained operators not only respond effectively in crises but also enhance compliance records, ensuring continued approval from Saudi Civil Defense authorities.

This blend of human skill and technological advancement defines DARS’s operational excellence in fire suppression technology. The company’s teams combine engineering expertise with practical field experience, making them an essential partner for long-term system reliability.

Environmental Shifts: The Move Toward Fluorine-Free Foam

The global firefighting industry is undergoing a significant transition. Traditional foams containing PFOS and PFAS, long valued for their performance, are now being phased out due to environmental and health concerns. These compounds, known as “forever chemicals,” persist in ecosystems and accumulate over time. In response, Saudi authorities are adopting new regulations to align with international standards, requiring that all foam systems shift toward fluorine-free formulations by 2026.

This shift marks a turning point for both manufacturers and contractors. DARS has already begun integrating eco-friendly alternatives that match or exceed the efficiency of older foams while fully complying with the Saudi Technical Regulations for Fire Control Materials. These next-generation agents offer high burn-back resistance, faster cooling, and minimal environmental footprint.

In addition to compliance, adopting fluorine-free foam demonstrates corporate responsibility. Many of DARS’s industrial clients particularly in oil, logistics, and aviation now prefer sustainable solutions that support Saudi Vision 2030’s environmental objectives. It’s a shift that reflects both operational advancement and national progress.

Smart Monitoring and Digital Fire Safety Management

As digital transformation spreads through every sector, fire suppression installation and monitoring have evolved beyond manual checks. Modern systems now use sensors and cloud-based dashboards to continuously track foam levels, valve positions, and pressure readings. These smart monitoring tools issue real-time alerts when irregularities occur, reducing downtime and improving preventive maintenance efficiency.

DARS integrates these digital capabilities into its fire safety solutions portfolio, offering centralized system management for large industrial facilities. Through IoT-enabled panels and predictive analytics, operators can visualize system health, simulate test scenarios, and generate automated compliance reports. This digital layer bridges traditional fire protection with the future of emergency response systems, ensuring faster decision-making when every second counts.

For industrial clients handling high-risk materials, such intelligent monitoring minimizes human error and guarantees that foam suppression remains effective at all times. It also enhances sustainability by optimizing foam concentrate usage and reducing waste, an important step toward both safety and environmental balance.

Innovations Transforming Foam Suppression Systems

The innovation landscape in foam suppression technology is expanding rapidly. One major advancement lies in proportioning systems, which now use digital flow meters for unmatched accuracy. Traditional mechanical proportioners often required manual calibration, but modern systems self-adjust to ensure correct foam-to-water ratios under all pressure conditions.

Another breakthrough is modular foam generator design. These compact units simplify system installation and reduce maintenance complexity, making them ideal for facilities with space constraints. In high-expansion systems, new nozzle geometries improve bubble uniformity, increasing coverage and reducing foam consumption.

DARS stays at the forefront of these innovations by collaborating with certified international partners and continuously updating its product line to meet NFPA, UL, and Saudi Civil Defense standards. These efforts underscore the company’s strategic focus on quality and precision, ensuring every system provides effective fire hazard prevention under the most demanding conditions.

The Intersection of Safety and Sustainability

Saudi Arabia’s industrial expansion brings an equally strong responsibility toward sustainability. Foam suppression systems now serve not just as fire protection equipment, but also as tools for achieving safer, cleaner, and more efficient industrial operations. By integrating environmentally friendly foams and automated maintenance systems, DARS ensures clients meet both local and international sustainability targets.

This balance of protection and environmental care aligns with Saudi Vision 2030’s goal of fostering industrial growth while minimizing ecological impact. It also reflects a global trend: modern fire suppression is no longer about reactive measures but proactive management preventing damage before it begins.

DARS’s projects across the Kingdom demonstrate that safety and sustainability can coexist. By combining compliance, innovation, and environmental responsibility, each installation contributes to a safer industrial ecosystem for future generations.

Designing Effective Foam Suppression Systems

Building a reliable foam suppression system starts long before installation. It begins with a deep understanding of the facility’s operational risks, the types of flammable liquids present, and the environmental conditions that might affect performance. In Saudi Arabia, where industries operate across deserts, ports, and energy fields, each project demands a tailored engineering approach.

Designers must consider factors such as fuel type, storage method, and room ventilation to determine the most effective foam expansion rate and discharge pattern. This process requires collaboration between fire protection engineers, safety officers, and contractors to achieve a balanced design that meets both regulatory and operational requirements. DARS takes this process further by integrating advanced modeling tools that simulate potential fire scenarios, ensuring every installed system performs flawlessly under pressure.

Key Industries Benefiting from Foam Suppression in Saudi Arabia

Foam suppression systems have become essential for numerous sectors driving the Kingdom’s economy. In oil and gas, they protect storage tanks, pipeline manifolds, and processing units from devastating hydrocarbon fires. At airports, foam-based systems safeguard refueling areas and hangars, where high volumes of jet fuel make rapid response essential.

The chemical and manufacturing industries rely on these systems for production lines that use solvents, paints, and lubricants. Meanwhile, logistics hubs and large-scale warehouses use them to protect packaged goods and stored fuels. In each of these cases, the system’s design adapts to the space from fixed overhead sprinklers in enclosed rooms to mobile foam monitors used outdoors.

DARS’s experience across all these environments gives it the ability to tailor fire safety solutions to the specific hazards of each sector, ensuring compliance with Saudi Civil Defense Safety Codes and global standards such as NFPA 11 and NFPA 16.

Integrating Foam Suppression with Broader Fire Protection Systems

A foam system is most effective when it operates as part of a coordinated network. Integration with detection, alarm, and emergency lighting systems allows for faster activation and improved situational awareness. Modern fire protection now focuses on interconnected systems that work together to prevent escalation.

For example, once a detector senses a rise in temperature or smoke particles, it triggers an alarm and sends a signal to the control unit, which immediately activates the foam proportioner and discharge valves. The system then releases foam through pre-calibrated nozzles, ensuring optimal coverage of the hazard area. Simultaneously, the control system notifies facility operators and emergency responders through the centralized fire control systems, allowing quick evacuation and targeted intervention.

DARS specializes in such holistic designs, combining automatic foam systems with other suppression technologies like dry chemical agents or clean gases. This layered defense strategy offers both flexibility and redundancy, a must for mission-critical operations.

Compliance and Certification: A Continuous Responsibility

Regulatory compliance doesn’t end once a system is installed. In Saudi Arabia, companies are obligated to maintain updated certifications for every fire suppression installation, including annual testing reports, calibration records, and technician licenses. These documents serve as proof of readiness during Civil Defense inspections.

DARS ensures its clients remain fully compliant by maintaining transparent records for all maintenance activities, foam quality verifications, and equipment upgrades. This diligence not only satisfies government regulations but also enhances a company’s reputation for safety and accountability.

In a sector where compliance gaps can lead to serious penalties or operational shutdowns, such consistency provides peace of mind. More importantly, it safeguards workers, assets, and community safety reflecting the essence of responsible industrial management.

Selecting the Right Foam Suppression Partner

Choosing a contractor for fire protection is more than a procurement decision; it’s a long-term partnership that affects safety, sustainability, and compliance. The right provider must understand local regulations, possess engineering expertise, and maintain a proven record of delivering complex safety systems under Saudi standards.

DARS’s reputation is built on its role as both contractor and consultant. Beyond installation, it offers end-to-end lifecycle support from feasibility studies and system design to maintenance and renewal. Its experience across multiple high-risk sectors gives clients confidence that every project aligns with both NFPA and Saudi Building Code requirements.

When evaluating providers, decision-makers should prioritize these elements:

- Technical Expertise: Proven ability to design and maintain foam suppression in complex environments.

- Regulatory Compliance: Familiarity with Saudi Civil Defense, NFPA, and environmental mandates.

- Sustainability Commitment: Adoption of fluorine-free foams and eco-friendly technologies.

A partner that excels in all three ensures long-term protection and operational integrity.

Case Example: Implementing Foam Suppression in Fuel Storage Facilities

Consider a large fuel storage terminal near Dammam, where multiple tanks containing diesel and aviation fuel require simultaneous protection. In such a setting, traditional sprinklers are insufficient. Engineers from DARS designed a hybrid solution combining fixed foam chambers, mobile monitors, and automatic detection integration.

The system was calibrated to discharge low-expansion foam for direct surface cooling and high-expansion foam for vapor suppression inside containment areas. Regular testing confirmed rapid response times and minimal foam waste proving not only regulatory compliance but operational efficiency.

This example demonstrates how a system tailored to specific conditions can protect assets worth millions while ensuring adherence to environmental and safety codes. It highlights the importance of combining engineering insight with field experience, something DARS continues to provide across all its industrial partnerships.

The Future of Foam Suppression in Saudi Arabia

As the Kingdom accelerates industrial development under Vision 2030, the demand for innovative and sustainable fire suppression technology will continue to grow. The next generation of foam systems will integrate advanced analytics, remote diagnostics, and AI-driven predictive maintenance. These enhancements will allow operators to anticipate risks before they occur, making fire protection not just reactive but intelligent.

The transition toward digital monitoring and fluorine-free foams also reflects Saudi Arabia’s environmental and economic priorities. By merging innovation with sustainability, the nation is setting new benchmarks for global fire hazard prevention practices. DARS remains positioned at the center of this evolution, combining technical expertise, compliance leadership, and environmental responsibility.

Key Takeaways and Final Thoughts

Foam suppression systems stand as a cornerstone of industrial safety in Saudi Arabia. Their role extends beyond extinguishing flames; they embody a commitment to compliance, sustainability, and human protection. Every system designed and maintained by DARS represents a promise of reliability, precision, and innovation.

The combination of regulatory alignment, environmentally responsible materials, and smart monitoring defines the future of fire protection equipment in the Kingdom. Organizations that adopt these standards not only safeguard their operations but also contribute to a safer and more sustainable national landscape.

By investing in advanced foam suppression systems, Saudi industries affirm their dedication to progress protecting what matters most: lives, assets, and the nation’s future.