Why Preventive Maintenance Matters More Than Ever

Preventive maintenance is the foundation of any effective fire protection strategy. It’s the ongoing process of inspecting, testing, cleaning, and replacing system components before failures occur. For a company like DARS, which specializes in applying and developing advanced safety systems, preventive maintenance is not just a technical task, it’s a commitment to protecting lives and property across Saudi Arabia.

In a country where industrial growth and infrastructure expansion continue at an exceptional pace, maintaining safety systems to meet both compliance standards and operational reliability has become a national priority. Preventive maintenance ensures that every pump, alarm, and sprinkler operates at peak performance when it matters most.

What Is Preventive Maintenance?

Preventive maintenance (PM) is a proactive approach aimed at reducing risks and ensuring equipment reliability through scheduled upkeep. Instead of waiting for a breakdown or fire incident to occur, the PM anticipates potential faults and addresses them early.

In fire protection systems, preventive maintenance includes:

- Regular system inspections for leaks, corrosion, or faulty sensors.

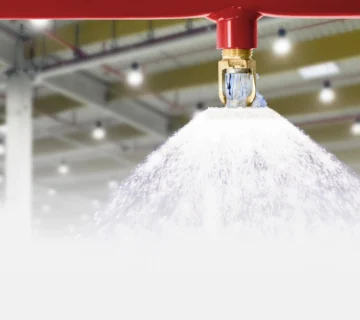

- Functional testing of alarms, control panels, extinguishers, and sprinkler systems.

- Cleaning detectors, checking water flow, and calibrating pressure gauges.

This consistent cycle of attention not only safeguards physical assets but also promotes cost efficiency by avoiding expensive emergency repairs and unplanned downtime.

The Role of Preventive Maintenance in Fire Safety

Every second counts in a fire emergency. A neglected system could fail when needed most, putting both lives and infrastructure at risk. In Saudi Arabia, adherence to Civil Defense and NFPA standards ensures that fire protection systems remain fully operational under pressure.

According to the NFPA 25, which governs the inspection, testing, and maintenance of water-based fire systems, preventive maintenance is mandatory, not optional. Compliance protects businesses from penalties, insurance complications, and catastrophic losses.

DARS integrates this philosophy into every project it handles, ensuring clients across sectorscommercial, industrial, and residential benefit from structured preventive programs tailored to their environments.

Preventive Maintenance in the Saudi Context

Saudi Arabia’s climate presents unique challenges: intense heat, high dust levels, and fluctuating humidity. These conditions accelerate equipment wear and can reduce asset longevity if systems aren’t serviced routinely.

Facilities such as factories, warehouses, and high-rise buildings rely on DARS’s maintenance schedules designed to mitigate these environmental effects. This includes frequent cleaning of smoke detectors, lubrication of mechanical valves, and inspection of piping networks for pressure stability.

Beyond technical upkeep, preventive maintenance in the Kingdom aligns with Saudi Civil Defense and High Commission for Industrial Security (HCIS) regulations. These bodies define the maintenance intervals, testing standards, and certification requirements that companies must follow.

For instance, according to Saudi Civil Defense codes, fire pumps and alarm systems must undergo scheduled testing, and records must be kept for inspection by authorities. Failure to maintain such documentation could lead to penalties or revoked safety certifications.

What Preventive Maintenance Includes

A well-executed preventive maintenance plan encompasses several interlinked activities, each contributing to system health and reliability.

- Visual Inspection: Checking valves, gauges, and control panels for leaks, corrosion, or physical damage.

- Functional Testing: Simulating alarm activation, flow testing, and verifying communication between system components.

- Component Servicing: Cleaning sprinkler heads, replacing expired extinguishers, and calibrating pressure regulators.

These steps ensure operational performance remains consistent while minimizing downtime that could interrupt essential safety coverage.

The Maintenance Schedule: Frequency and Best Practices

Every preventive maintenance plan is built on a precise maintenance schedule aligned with regulatory guidelines and system type. Based on NFPA 25, Saudi Arabia’s Civil Defense mandates the following intervals:

- Weekly and Monthly: Quick visual checks to confirm alarm panel status and valve positioning.

- Semi-Annually: Functional testing, cleaning, and minor part replacements.

- Annually: Comprehensive audits, including hydrostatic testing, pressure verification, and documentation updates.

However, each facility’s needs differ. Industrial plants operating under harsh conditions may require more frequent inspections to ensure equipment reliability and safety system integrity. DARS works with clients to customize their maintenance intervals based on building type, risk level, and operational intensity.

Who Should Conduct Preventive Maintenance?

Preventive maintenance for fire protection systems must be handled by certified professionals with both local and international credentials. In Saudi Arabia, service providers must be licensed by Civil Defense and adhere to NFPA standards.

DARS’s team includes engineers and technicians trained under the HCIS and manufacturer-specific programs, ensuring each maintenance task is executed with precision. Their qualifications guarantee adherence to compliance requirements while maintaining system integrity.

This professional approach also supports transparency and accountability. Every inspection, repair, or replacement is documented and logged, forming an essential part of compliance audits and insurance assessments.

The Importance of Documentation and Compliance

Documentation is often overlooked but is one of the most vital components of preventive maintenance. Keeping detailed records of system inspections, test results, and repairs ensures that both facility owners and authorities have verifiable proof of compliance.

These documents support regulatory audits and serve as valuable evidence in case of an incident or insurance claim. According to NFPA guidelines, maintenance logs should include equipment details, service dates, technician credentials, and corrective actions taken.

In Saudi Arabia, DARS encourages clients to digitize these records through modern reporting tools, making it easier to track performance, predict future needs, and ensure uninterrupted fire protection coverage.

Challenges in Preventive Maintenance of Fire Protection Systems

Even with advanced planning, maintaining fire protection systems in Saudi Arabia presents real-world challenges. Environmental factors like dust, sand, and extreme heat can cause rapid deterioration of mechanical components and electrical sensors.

Furthermore, some remote regions face limited access to certified maintenance providers, delaying critical interventions. Balancing these challenges while maintaining strict compliance standards requires strategic scheduling and reliable partnerships with professional service providers.

Another key challenge lies in minimizing disruption to daily operations. For businesses running around the clock, system shutdowns during maintenance can affect productivity. DARS addresses this by scheduling work during off-peak hours and implementing partial-system testing to ensure continuity.

Technology and the Future of Preventive Maintenance

Technology is reshaping how preventive maintenance is managed and tracked. Smart systems equipped with IoT sensors can monitor fire equipment performance in real-time, alerting teams to anomalies before they escalate.

Automated reporting tools now log test results, send reminders for scheduled inspections, and track operational performance metrics across multiple sites. Remote diagnostics also reduce the need for on-site visits, improving both efficiency and response times.

By integrating these innovations, DARS enables clients to transition from traditional maintenance routines to predictive maintenance models that offer greater insight and control.

Optimizing Performance and Compliance through Smart Preventive Maintenance Strategies in Saudi Arabia

Building a Culture of Reliability

The essence of preventive maintenance lies not only in performing regular checks but in building a culture of reliability within every organization. For DARS, this means embedding maintenance thinking into daily operations where system performance, documentation, and safety awareness become second nature. A preventive mindset ensures that issues are addressed before they become risks, reinforcing equipment reliability and operational continuity.

In Saudi Arabia’s growing industrial landscape, where factories, hospitals, and high-rise buildings rely on uninterrupted protection, this mindset is vital. Routine maintenance transforms from a regulatory requirement into a business strategy, one that minimizes downtime and preserves cost efficiency while safeguarding lives.

Enhancing System Reliability through Data

Modern preventive maintenance is driven by data. Every inspection, test, or repair generates valuable insights about the system’s condition and performance trends. By tracking metrics such as response times, water pressure consistency, and sensor accuracy, companies can identify early signs of deterioration.

DARS leverages data-driven tools that consolidate these metrics into detailed maintenance reports. Over time, patterns emerge that allow technicians to predict when specific components will need servicing or replacement. This predictive capability reduces emergency repairs and ensures continuous compliance with Civil Defense and NFPA guidelines.

When integrated with smart platforms, this data becomes even more powerful. Real-time monitoring via IoT sensors enables remote supervision, alerting teams the moment abnormalities are detected. These insights allow for quick decision-making, reducing risks and enhancing system inspection efficiency.

From Scheduled Maintenance to Predictive Maintenance

Preventive maintenance has long relied on fixed schedules, weekly, monthly, and annual routines. But with technological advancement, the industry is shifting toward predictive maintenance, where actions are triggered by data rather than time.

Predictive models use real-time analytics to detect early deviations from normal operation. For example, a sudden pressure drop in a sprinkler line or a delayed alarm response could indicate the need for intervention before failure occurs. DARS integrates such technology into its service framework, helping clients move beyond routine checklists toward performance-based maintenance.

This shift not only improves operational performance but also aligns with global safety trends encouraging digital transformation in facility management. Predictive systems minimize unnecessary downtime and extend asset longevity, delivering significant savings over the system’s lifespan.

Meeting Compliance Standards with Precision

In the Kingdom of Saudi Arabia, compliance is not simply a regulatory hurdleit’s a framework for accountability and protection. Every fire protection system must meet the stringent requirements set by Saudi Civil Defense and international standards like NFPA 25.

DARS’s preventive maintenance programs are meticulously designed to ensure all systems stay audit-ready. This means every valve test, alarm activation, and report is documented and accessible for inspection. Compliance logs are updated in digital format to streamline verification during government audits or insurance assessments.

Moreover, the company’s adherence to HCIS (High Commission for Industrial Security) standards reinforces the integrity of its processes, particularly for high-risk industries such as oil, gas, and manufacturing. This commitment to compliance underlines DARS’s position as a trusted contractor in the field of safety and protection systems.

The Human Factor: Training and Competence

While automation and digital systems enhance efficiency, preventive maintenance ultimately depends on human expertise. Technicians must be skilled in diagnostics, familiar with code requirements, and trained to make informed judgments during inspections.

At DARS, continuous training ensures that every team member remains updated with evolving technologies and regulations. Workshops on NFPA updates, new testing methodologies, and safety protocols help maintain a consistent level of excellence across all projects.

This human element also reinforces trust. Clients know that every inspection, whether a quick sensor calibration or a full system audit is conducted by qualified professionals who understand the gravity of their responsibility.

Documentation as a Strategic Tool

Documentation has evolved beyond a compliance necessity; it’s now a core strategy for long-term maintenance success. Well-kept records allow for trend analysis, budgeting forecasts, and system performance comparisons across facilities.

DARS helps clients digitize these logs, ensuring traceability from the first inspection to the most recent update. When a system passes a test, the data is stored securely, often linked to IoT dashboards that visualize historical trends. If a component shows recurring issues, the system alerts maintenance planners to schedule replacements proactively.

This level of transparency improves not only compliance but also communication between facility managers and regulatory inspectors. It bridges the gap between maintenance execution and strategic planning, allowing safety management to become an integral part of operational excellence.

Overcoming Environmental and Logistical Challenges

Operating in Saudi Arabia presents unique obstacles for preventive maintenance teams. Extreme temperatures, frequent dust storms, and long distances between industrial zones can complicate service delivery. Electrical panels may overheat, and outdoor alarm units may accumulate debris that affects functionality.

DARS’s approach involves customized strategies for each environment. Coastal areas prone to humidity receive more frequent corrosion checks, while desert installations undergo enhanced cleaning and component lubrication. Mobile maintenance units are also deployed to remote locations, ensuring timely service without compromising system reliability.

By addressing these local conditions proactively, the company not only maintains equipment reliability but also upholds the continuity of safety operations across diverse sectors from logistics hubs to oil refineries and residential complexes.

Integrating Preventive Maintenance with Facility Management

Preventive maintenance functions best when integrated into a broader facility management system. Rather than existing as a separate process, it should align with daily operations, energy management, and risk assessment programs.

For instance, maintenance schedules can be coordinated with occupancy patterns or production cycles to minimize disruption. Integrating fire system maintenance into enterprise management software allows for unified dashboards that track both safety and operational KPIs.

DARS promotes this integration through collaboration with facility managers and consultants, ensuring preventive maintenance contributes directly to the overall performance of a building’s infrastructure. This holistic perspective transforms maintenance from a cost center into a driver of value and sustainability.

Aligning with Vision 2030 and National Safety Goals

Saudi Arabia’s Vision 2030 emphasizes sustainability, efficiency, and innovation in every sector, including safety and infrastructure. Preventive maintenance plays a direct role in supporting these goals by enhancing the reliability of national assets and reducing resource waste.

Through proactive care, DARS contributes to the country’s broader mission of fostering safe, modern, and compliant infrastructure. By merging advanced technologies with national safety codes, the company strengthens the resilience of fire protection systems that form the backbone of public safety.

This alignment also demonstrates how preventive maintenance is more than an operational requirement; it’s an investment in the future, contributing to sustainable urban growth and a culture of preparedness that aligns with the Kingdom’s vision.

Long-Term Preventive Maintenance Strategies and the Future of Fire Safety in Saudi Arabia

The Evolution Toward Proactive Maintenance

As Saudi Arabia advances its industrial and urban development, the shift from reactive to proactive maintenance continues to define the nation’s approach to safety. DARS stands at the forefront of this evolution, ensuring that preventive maintenance not only safeguards buildings but also drives long-term operational efficiency.

Proactive maintenance is built on foresight rather than response. It requires a structured plan, consistent data analysis, and the integration of technology to anticipate system behavior. In fire protection, this approach translates into fewer emergency breakdowns, reduced costs, and enhanced equipment reliability across all sectors.

Creating Sustainable Maintenance Frameworks

Sustainability in fire safety depends on how well maintenance systems are designed to adapt and evolve. DARS’s long-term frameworks emphasize three core elements: consistency, documentation, and continuous improvement.

By developing structured maintenance plans, organizations can predict service timelines, manage spare parts efficiently, and ensure all components are replaced before failure. Consistency ensures that safety systems remain dependable; documentation supports traceability and compliance; and improvement ensures that lessons from past inspections shape future procedures.

These frameworks align with Saudi Civil Defense requirements and global best practices, allowing clients to operate within fully compliant, auditable safety environments.

Cost Efficiency Through Smart Maintenance

A well-planned preventive maintenance program reduces costs not by cutting corners, but by optimizing timing and resources. Emergency repairs are typically three to five times more expensive than scheduled servicing. By addressing issues early, DARS helps clients save both time and money while maintaining high safety standards.

This cost efficiency is further amplified by digital tools that streamline scheduling, reporting, and inventory control. When all maintenance activities are planned around data-backed insights, unnecessary expenditures such as replacing parts too early or delaying inspections are eliminated. Over time, this precision supports financial sustainability and reinforces confidence in the system’s reliability.

Measuring Performance and ROI

For organizations to recognize the true value of preventive maintenance, measurement is essential. The effectiveness of maintenance can be evaluated through metrics such as reduction in emergency incidents, decrease in repair frequency, and improvement in operational performance.

DARS integrates reporting tools that visualize these metrics, allowing facility managers to monitor progress and justify investment in ongoing maintenance. A positive ROI becomes evident when systems function seamlessly during audits, insurance evaluations, or real emergencies prove that consistent preventive action pays off both financially and operationally.

The Role of Digital Transformation

Digital transformation continues to reshape how safety contractors approach preventive maintenance. Cloud-based maintenance management systems now serve as centralized platforms for scheduling, record-keeping, and alert generation. These digital solutions eliminate human error, ensure accuracy, and provide accessible maintenance histories for every asset in the system.

IoT-enabled sensors also contribute to this transformation by enabling real-time monitoring of safety systems. Alerts can be triggered for unusual temperature fluctuations, water flow irregularities, or electrical faults, allowing technicians to act immediately. Through this integration, DARS delivers not only service but also intelligent insight transforming maintenance from a manual task into a data-driven discipline.

Collaboration Between Stakeholders

Effective preventive maintenance requires coordination between multiple stakeholders/engineers, safety officers, facility managers, and regulatory inspectors. Each plays a role in ensuring the system’s ongoing health.

DARS fosters collaboration by creating transparent communication channels among these parties. Digital reporting tools enable real-time sharing of inspection results, ensuring everyone is informed about maintenance progress and compliance status. This partnership approach helps maintain alignment between operational teams and safety regulations, minimizing misunderstandings and strengthening accountability.

Such collaboration also extends to equipment manufacturers and software providers, ensuring that spare parts, updates, and upgrades remain consistent with system requirements and local compliance standards.

Continuous Training and Knowledge Transfer

No maintenance plan can succeed without human expertise. As fire safety technologies advance, new systems demand specialized knowledge and technical adaptability. DARS invests heavily in training programs that equip technicians and client teams with up-to-date industry skills.

Workshops focus on new inspection methods, sensor calibration, and understanding the evolving codes of NFPA and Civil Defense. Knowledge sharing not only improves technical competence but also builds confidence within the client’s in-house teams, fostering a shared sense of ownership over safety performance.

By combining certified training with field mentorship, DARS ensures that preventive maintenance excellence is not limited to its own operations but extended throughout its clients’ organizations.

Building Trust Through Transparency

Trust forms the foundation of every maintenance partnership. Clients depend on contractors not just to service systems, but to protect people and assets. DARS builds this trust through transparency in every process from inspection findings to cost reports.

Each maintenance session concludes with clear documentation detailing what was inspected, what was repaired, and what requires follow-up. Clients have complete visibility into their system’s condition, ensuring accountability at every step. This open communication reinforces DARS’s reputation for integrity and positions it as a benchmark for fire protection excellence in Saudi Arabia.

The Future of Preventive Maintenance in Fire Safety

The future of fire protection in Saudi Arabia lies in intelligent, predictive maintenance ecosystems where every sensor, valve, and alarm is part of a connected network. Artificial intelligence will soon analyze years of maintenance data to forecast risks and automatically schedule interventions.

As these innovations evolve, DARS is committed to leading the transformation. The company’s strategy centers on integrating new technologies without compromising the human oversight that ensures ethical and reliable maintenance practices. The blend of human expertise and digital intelligence will define the next generation of preventive maintenance, where safety is not just maintained but continually enhanced.

This forward-thinking approach aligns with Saudi Arabia’s Vision 2030 ambitions for sustainability and digital advancement, ensuring that every structure, industrial, commercial, or residential meets the highest global standards for safety and resilience.

Conclusion: A Future Secured by Prevention

Preventive maintenance is more than a regulatory requirement, it’s a philosophy of foresight, precision, and care. By prioritizing consistent inspections, data-informed strategies, and transparent documentation, organizations can ensure their fire protection systems perform flawlessly when most needed.

For DARS, preventive maintenance is a long-term partnership between technology, expertise, and trust. It represents the company’s unwavering commitment to protecting both property and lives, ensuring that every system under its care operates at peak efficiency, in full compliance with the Saudi Civil Defense, NFPA, and HCIS standards.