Why Foam Systems Matter

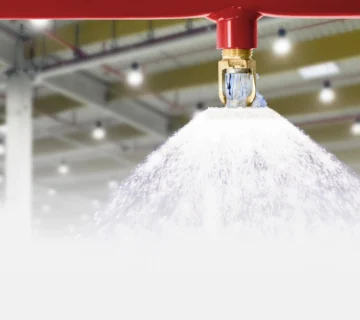

A foam system is one of the most reliable and widely used technologies for controlling fires that involve flammable liquids and hazardous substances. By mixing foam concentrate, water, and air, these systems create a foam blanket that cools the fire, isolates the fuel, and prevents vapors from reigniting. In Saudi Arabia where industries such as oil & gas, petrochemicals, aviation, and large-scale warehousing dominate the demand for effective fire suppression systems is not just a matter of operational safety; it is a matter of protecting national assets, lives, and infrastructure.

The relevance of foam systems in the Kingdom is further underlined by strict civil defense requirements and NFPA standards that set the benchmark for safe installation and operation. Companies like DarAlhmaya play a crucial role in providing certified fire protection solutions that align with both local and international codes, ensuring businesses achieve full building safety compliance.

What Are the Different Types of Foam Fire Suppression Systems?

Foam systems are not one-size-fits-all. Different industries require tailored solutions depending on the type of fire hazard, fuel characteristics, and environmental considerations.

Low, Medium, and High Expansion Foam Systems

- Low Expansion foam is dense and highly effective for hydrocarbon fires such as those in oil depots or refineries.

- Medium Expansion foam is ideal for spill fires in warehouses or chemical storage areas, as it spreads quickly over large surfaces.

- High Expansion foam is lightweight, filling large enclosed spaces such as aircraft hangars or LNG facilities.

Each type has its own foam expansion ratio, making it critical for fire safety contractors to conduct proper hazard analysis before recommending a system.

Principles of Foam Fire Suppression

At the core, a foam system works by excluding oxygen and suppressing vapor release. This double action means the fire is not only extinguished but also prevented from reigniting. Unlike fire sprinkler alternatives, foam systems target liquid fuel fires more effectively, where water alone would spread the hazard.

Specific Applications

Industries in Saudi Arabia deploy foam systems strategically:

- Warehouses housing chemicals or flammable goods.

- Aircraft hangars requiring rapid fire blanket coverage.

- LNG ponds and petrochemical plants, where vapor suppression is vital.

This variety underscores why foam is not just a system it is an entire strategy for industrial fire safety.

Foam Deluge Systems: Mechanism and Industrial Applications

One of the most powerful types is the foam deluge system, which releases large volumes of foam instantly through open nozzles. These are commonly used in tank farms, aviation facilities, and high-hazard industrial complexes. Their purpose is simple: flood the risk area before fire can spread.

How Does a Foam Fire Suppression System Work?

Understanding how a foam system works helps facility managers appreciate the importance of quality design, installation, and maintenance.

The Foam Generation Process

A foam system operates by mixing three elements:

- Foam concentrate – a chemical agent stored in tanks.

- Water – supplied through pumps or municipal connections.

- Air – drawn in naturally or through mechanical means.

When these combine, they create a stable foam blanket that suppresses fire while cooling the fuel surface.

Suppression Mechanism

The foam blanket serves multiple functions: it smothers flames, cools the fuel, and prevents vapors from escaping. This mechanism makes foam systems especially effective for hydrocarbon and polar solvent fires. In sectors like oil & gas, where risk is high and damage costs are immense, foam suppression is indispensable.

Importance of Foam Concentrate Quality

The effectiveness of the foam blanket largely depends on the foam concentrate used. Poor-quality or expired concentrates can compromise the system’s reliability. Reputable providers ensure foam concentrates comply with international certifications and are tested regularly to maintain standards.

For example, Eurosafe Global emphasizes that foam type and quality directly impact system performance a reminder of why professional suppliers matter.

Regulatory and Compliance Requirements for Foam Systems in Saudi Arabia

Saudi Arabia has a unique regulatory environment where civil defense requirements intersect with international best practices. Organizations that fail to comply face penalties, legal action, and in some cases, suspension of operations.

Saudi Civil Defense Requirements Overview

The Saudi Civil Defense authority mandates strict fire protection measures across industrial and commercial facilities. Foam systems must be installed by approved contractors and undergo periodic inspection to ensure readiness.

NFPA Standards and Saudi Building Code (SBC)

Foam systems are also required to align with NFPA standards globally recognized guidelines for fire suppression systems and the Saudi Building Code (SBC), which integrates safety protocols into structural planning. For businesses, this dual compliance ensures both global credibility and local approval.

A detailed resource by LifeCo UK highlights how non-compliance can lead to fines, operational delays, and reputational damage.

Licensing, Inspection, and Maintenance Mandates

Only licensed fire safety contractors are permitted to install or maintain foam systems. Annual inspections are mandatory, with results submitted to the Civil Defense. This ensures that systems are not only compliant at the point of installation but also maintained throughout their operational life.

Penalties for Non-Compliance

Failure to meet fire protection standards can result in heavy penalties. More importantly, it exposes companies to catastrophic risks, including asset loss and human casualties. Compliance is not simply a legal obligation it is an operational safeguard.

How Foam Fire Suppression Systems Are Designed and Installed

While foam systems may appear straightforward, their design and installation require expertise. Every site has unique hazards, and a cookie-cutter solution will not suffice.

Risk Assessment and Hazard Evaluation

The first step in system design is a detailed risk assessment. Certified experts evaluate the type of fuel present, potential ignition sources, and environmental conditions. This ensures the system matches the hazard profile of the facility.

System Components

A standard foam system typically includes:

- Foam generators or proportioners to mix concentrate with water.

- Storage tanks for foam concentrate.

- Pipes, nozzles, and monitors to distribute foam across the hazard area.

Each component must be carefully selected and calibrated to ensure reliable performance in an emergency.

Integration with Other Fire Protection Systems

Foam systems rarely operate in isolation. They are often integrated with sprinklers, fire alarms, and emergency response protocols. This layered approach ensures rapid detection, suppression, and evacuation.

For example, Perfect Vision KSA highlights the effectiveness of combining foam systems with early detection sensors for a stronger fire suppression strategy.

Installation Best Practices and Site Considerations

During installation, contractors must account for site-specific challenges such as space limitations, climate, and existing infrastructure. Incorrect placement of nozzles or miscalculated pressure levels can compromise the entire system.

DarAlhmaya, through its projects portfolio, showcases multiple successful installations that combine global best practices with deep knowledge of local compliance standards.

Foam System Fire Suppression in Saudi Arabia: Maintenance, Challenges, and Practical Considerations

How Often Should Foam Fire Suppression Systems Be Maintained and Tested?

Designing and installing a foam system is only the beginning of its lifecycle. To ensure continuous protection, ongoing maintenance and scheduled testing are essential. In Saudi Arabia, the civil defense requirements mandate routine inspections, and adherence to NFPA standards provides international credibility. This dual approach ensures that foam systems are not only compliant but also reliable when they are needed most.

A foam system should be maintained at regular intervals to check for issues such as degraded foam concentrate, blocked nozzles, or pump malfunctions. The testing process often involves proportioning checks, discharge simulations, and water supply verification. These activities ensure that when a fire occurs, the system will deploy foam effectively and cover the hazard area within seconds.

Systematic maintenance also protects businesses from insurance complications. Many insurers require evidence of regular system testing before honoring claims. By keeping inspection logs and compliance certificates updated, facility managers safeguard both operational continuity and financial protection.

Common Maintenance Practices for Foam Systems

The reliability of a foam system depends on attention to detail during every inspection. One of the most important aspects is verifying the foam concentrate. If stored improperly or left unused for extended periods, concentrates may separate or lose their chemical integrity. Testing ensures that the foam produced maintains its designed expansion ratio and suppression capability.

Pumps and proportioning devices are another critical area. If a pump fails during an emergency, the entire system is rendered ineffective. Regular pump activation and calibration confirm operational readiness. Nozzles and discharge equipment must also be inspected for blockages caused by dust, corrosion, or foreign particles. Even small obstructions can drastically reduce foam coverage, creating dangerous gaps in protection.

Beyond technical checks, training personnel to understand system operation is vital. In an emergency, untrained staff may hesitate or misuse control panels. Regular drills and demonstrations help bridge the gap between system reliability and human readiness.

The Importance of Regular System Testing

Testing a foam system goes beyond compliance. It is a direct measure of whether the system will perform as expected under real conditions. Full-scale discharge tests simulate actual fire suppression, confirming that foam blankets spread across the designated hazard zone. Such exercises are particularly crucial in facilities like aircraft hangars and petrochemical storage areas, where response time can mean the difference between containment and catastrophe.

In Saudi Arabia, both the Saudi Building Code (SBC) and NFPA emphasize the value of testing. Facilities that ignore these requirements risk operational shutdowns imposed by Civil Defense. More importantly, they risk unpreparedness in the face of emergencies. A tested and certified system offers peace of mind for stakeholders, employees, and regulators alike.

Challenges and Considerations in Foam System Operations

Even with best practices, foam systems present unique challenges. Understanding these helps organizations plan proactively rather than reactively.

Ensuring Foam Quality and Proportioning

The performance of a foam system is directly tied to foam quality. A system that delivers incorrect foam-to-water ratios will fail to suppress fires effectively. For example, a weak foam blanket may collapse quickly, leaving fuel exposed. Routine proportioning tests, using calibrated equipment, prevent such failures and keep systems reliable.

Indoor vs. Outdoor Applications

Operating environments significantly influence system performance. Outdoor installations, such as oil tank farms, must contend with wind, temperature fluctuations, and dust storms. Foam distribution can be disrupted in open spaces, requiring careful nozzle placement and higher discharge rates. Indoor environments, while more controlled, still demand precision to ensure full coverage without excessive foam accumulation that could hinder evacuation.

Environmental Considerations

Foam discharge introduces environmental responsibilities. Some older foams contained chemicals now classified as harmful to ecosystems. Modern alternatives emphasize biodegradable formulations that suppress fires effectively while minimizing environmental damage. However, even eco-friendly foams require cleanup after activation, adding cost and logistical considerations for facility managers.

Training for Emergency Response

Technology alone does not guarantee safety. Human readiness plays a decisive role in fire suppression. Staff must be trained to activate systems, understand manual overrides, and coordinate with external emergency response systems. Drills that combine foam system activation with evacuation exercises create a culture of preparedness within the organization.

Foam Systems and Risk Management in Saudi Arabia

A foam system should be viewed not as a standalone installation but as part of a comprehensive fire risk management strategy. In industries where flammable liquids dominate operations, the foam system forms the frontline defense. Yet it is only effective when paired with detection technologies, staff readiness, and compliance frameworks.

In Saudi Arabia, regulators encourage companies to integrate foam suppression with layered defenses. This may include early smoke detection, automatic alarms, and even fire sprinkler alternatives for non-liquid hazards. Together, these layers create redundancy, ensuring no single failure compromises safety.

DarAlhmaya’s risk management solutions emphasize this integrated approach, combining advanced technology with on-the-ground training and inspection services. This holistic perspective aligns with both operational realities and government expectations.

Environmental and Sustainability Considerations

Global trends increasingly highlight the environmental footprint of fire suppression systems. Saudi Arabia, with its Vision 2030 sustainability goals, is no exception. Older foams containing perfluorinated compounds (PFAS) are being phased out in favor of environmentally responsible alternatives. These modern foams maintain strong suppression capacity while reducing contamination risks to soil and water.

For businesses, adopting sustainable foam systems is not only about compliance but also about corporate responsibility. International partners and investors increasingly scrutinize environmental practices. By deploying eco-friendly foams, organizations signal alignment with global best practices while protecting their local environment.

Authoritative sources such as Best UST Arabia confirm that sustainable foams are now a leading trend across the region, balancing performance with environmental stewardship.

Training and Knowledge Transfer

Maintaining a foam system is not solely a technical process; it is also about transferring knowledge to those who manage facilities daily. Certified contractors may handle inspections and repairs, but facility staff must understand how systems operate. This includes knowing how to switch between automatic and manual activation, how to silence alarms, and how to communicate with Civil Defense during emergencies.

DarAlhmaya places emphasis on training as part of its fire protection solutions, recognizing that empowered staff form the bridge between system capability and real-world effectiveness. Without such training, even the most advanced foam system may underperform in the face of an actual fire.

Foam System Fire Suppression in Saudi Arabia: Innovations, Trends, and the Future

Latest Innovations in Foam Fire Suppression Systems

The fire protection industry continues to evolve, and foam systems are no exception. Advances in chemistry, digital monitoring, and integration technologies have transformed how these systems are designed and deployed. One of the most notable innovations is the development of environmentally friendly foam concentrates. These new formulas balance performance with sustainability, reducing the environmental impact without compromising fire suppression capacity.

Another innovation shaping the sector is smart proportioning technology. Digital sensors and automated control units now regulate the mix of water, foam concentrate, and air in real time. This guarantees consistent foam quality and eliminates the risk of human error during system activation. By ensuring the right balance, smart systems significantly improve reliability while reducing waste.

The Role of Smart Monitoring and Automated Delivery

Digital transformation has entered the world of fire protection. Modern foam systems are increasingly integrated with building management platforms, allowing real-time monitoring of system readiness. Facility managers can view foam concentrate levels, pump conditions, and nozzle status through a centralized dashboard. Automated alerts ensure that any deviation from operational standards is addressed immediately.

Automated foam delivery also represents a significant leap forward. Systems can now deploy foam based on hazard-specific parameters, adjusting discharge rates according to fire size and intensity. This level of precision reduces resource consumption and minimizes environmental cleanup requirements. In high-stakes environments such as petrochemical plants, automated delivery ensures that suppression efforts are both rapid and controlled.

Custom Solutions for High-Risk Industries

In Saudi Arabia, industries like oil & gas, aviation, and chemical storage facilities face unique risks. Standard systems cannot fully address these challenges, which is why custom-engineered foam solutions are becoming the norm. For example, aircraft hangars require rapid flooding capabilities to handle jet fuel fires, while LNG storage areas demand foam systems capable of suppressing vapor clouds.

Custom systems are designed through detailed hazard assessments, where engineers evaluate fuel types, storage configurations, and ignition sources. By tailoring foam system design to specific risks, organizations not only comply with civil defense requirements but also strengthen their resilience against catastrophic losses. Companies such as KFA Al Arabia highlight the importance of customization, offering deluge and high-expansion solutions designed for industrial-scale hazards.

Aligning with Saudi Vision 2030 and Global Standards

Saudi Arabia’s Vision 2030 places safety and sustainability at the core of industrial growth. Foam systems directly contribute to these objectives by ensuring operational continuity and minimizing fire-related risks. Organizations that adopt advanced foam suppression technologies align themselves with national goals while gaining credibility in global markets.

Compliance with NFPA standards and the Saudi Building Code also ensures that local systems remain competitive internationally. For businesses that collaborate with global partners, adherence to these frameworks strengthens trust and demonstrates commitment to best practices. Companies like AD Systems emphasize that certified systems not only protect facilities but also elevate corporate reputation.

Foam Systems as Part of Integrated Fire Protection

A modern safety strategy does not rely on a single technology. Foam systems are increasingly integrated with sprinklers, gas suppression systems, and advanced detection networks. This layered defense model ensures that each hazard type is addressed with the most effective tool. For example, while foam systems are ideal for flammable liquid fires, sprinklers may still play a role in suppressing solid fuel fires within the same facility.

Integration also extends to evacuation protocols and emergency response systems. By connecting foam suppression with alarms and automated communication, organizations create synchronized responses that protect both assets and lives. This holistic view of fire protection solutions is at the core of DarAlhmaya’s services, ensuring that clients receive not just equipment but a full safety ecosystem.

Emerging Trends in Industrial Fire Safety

The foam system market is being shaped by several key trends that reflect global and regional priorities. First is the shift toward environmentally sustainable foams, which align with increasing regulatory scrutiny. Second is the adoption of IoT-enabled monitoring, allowing remote oversight of critical safety systems. Third is the rise of hybrid solutions that combine foam suppression with complementary technologies for maximum coverage.

Another trend is the emphasis on predictive maintenance. With the help of AI-driven analytics, system performance data can now be analyzed to predict potential failures before they occur. This proactive approach reduces downtime and ensures that systems remain ready at all times. Authoritative sources such as Perfect Vision KSA confirm that predictive analytics is reshaping the maintenance landscape across the region.

The Future of Foam Systems in Saudi Arabia

Looking ahead, foam systems in Saudi Arabia are set to become smarter, greener, and more integrated. Research into next-generation foam concentrates promises faster knockdown times with lower environmental footprints. Meanwhile, automation and AI will continue to refine how systems respond to fires, ensuring precision and minimizing collateral damage.

For businesses, the future of foam suppression represents both an opportunity and a responsibility. Adopting advanced systems ensures compliance, but it also signals leadership in safety culture. Companies that invest early in innovation position themselves as industry benchmarks, aligning with Vision 2030’s vision of sustainable, world-class infrastructure.

Why Partnering with Certified Experts Matters

The complexity of foam systems makes professional expertise indispensable. From initial hazard analysis to system commissioning, certified contractors ensure compliance with both civil defense requirements and NFPA standards. More importantly, they bring practical knowledge of Saudi Arabia’s industrial environment, tailoring solutions to unique challenges such as extreme heat, dust exposure, and large-scale petrochemical operations.

DarAlhmaya has demonstrated this expertise through a range of successful projects, providing end-to-end solutions that integrate technology, compliance, and long-term reliability. By combining technical proficiency with regulatory knowledge, certified experts guarantee that foam systems deliver maximum protection.

Conclusion: Foam Systems as a Cornerstone of Industrial Safety

Foam systems stand at the intersection of technology, regulation, and human safety. In Saudi Arabia, where high-risk industries dominate, they provide critical protection against flammable liquid fires that water-based systems cannot control. Their role extends beyond compliance; they safeguard assets, ensure operational continuity, and protect lives.

The evolution of foam technology from sustainable concentrates to smart monitoring signals a future where safety is both advanced and environmentally responsible. For organizations, adopting these innovations is not optional; it is essential for staying aligned with global best practices and national priorities.

Ultimately, the effectiveness of a foam system lies in professional design, rigorous maintenance, and continuous adaptation to emerging risks. By working with certified fire safety contractors and embracing modern trends, Saudi businesses can ensure that their facilities remain protected, compliant, and future-ready.